Different Ways To Prevent Electric Overloads at Work

In any workplace, safety is the top priority. And every workplace has a unique set of safety hazards that owners and management should consider and minimize when possible. Many companies encounter electrical hazards due to the number of tools, devices, lighting fixtures, and more required for daily operations. If businesses don’t handle them carefully, electrical elements can cause dire harm and damage. Discover different ways to prevent electric overloads at work to save your company from electrical dangers.

Know the Signs of an Overloaded Circuit

Knowing the signs of an overloaded circuit can save your company from an accidental electrical explosion. A few indicators that you’re overworking different circuits around your company’s building include the following.

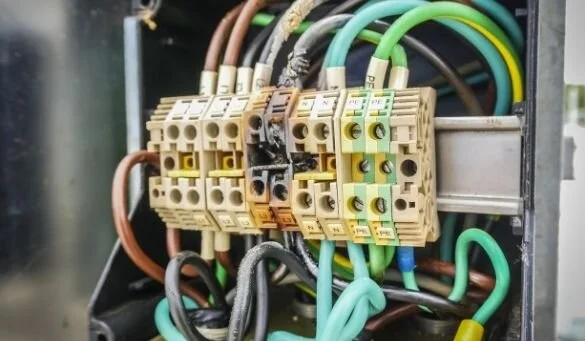

Circuits and outlets are hot on the surface or emitting smoke.

You notice your tools, equipment, or devices lacking sufficient performance and power.

The lights flicker or dim randomly.

There are whirring or buzzing sounds from outlets.

You smell something burning.

Get familiar with the signs of an overloaded circuit so that you know when to cut off the electrical current. Doing so can save your employees from potential harm and your building from costly damage.

Have Professionals Perform an Electric Load Analysis

Evaluating your electrical system is a complicated and hazardous task and you should leave it to the professionals. Therefore, find electrical consulting engineers to perform an electric load analysis.

An electric load analysis will help determine how much electrical current your company’s building and electrical system can truly handle, ensuring the safety of everyone on site. To gain a deeper understanding of what this assessment entails, review this guide to load analysis engineering.

Utilize Different Circuits for Different Equipment

It’s not uncommon for companies to have several devices plugged into one circuit. However, one of the different ways to prevent electric overloads at work is to note how much electrical power a device requires before fixing it to a circuit.

For equipment and devices that have steep power requirements, you should designate a separate circuit. Divvying up the electrical demand reduces the risk of an electrical outburst.